How do I remove the drive cable from my R/C boat?

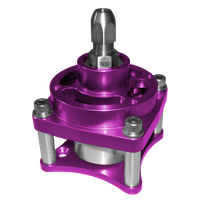

In order to remove your drive cable, you will first loosen the two set screws in the shaft ferrule. This will be the tapered cylinder between the transom and the shaft strut. Next, you will loosen the cable collet compression nut, which is the 9/16″ hex nut on the end of the collet. This will allow you to remove the cable. Slide the propeller shaft towards the rudder until it is released from the ferrule, pull the ferrule down slightly until it clears the bottom of the strut, and pull the cable straight out the back. Clean the cable, wipe any grease off it, spray with a penetrating oil to remove any trapped water or any other foreign fluids. Re-grease and store for the winter. To reinsert the cable, simply reverse the process.

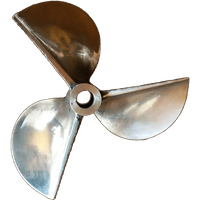

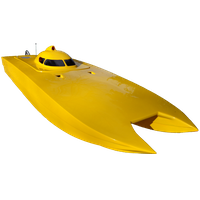

Propellers

Propellers

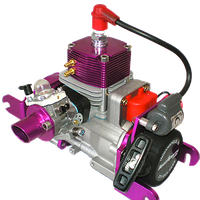

Zenoah Engine & Parts

Zenoah Engine & Parts