|

Frequently Asked Questions

| For BONZÍ’s official policies & procedures – Click to view

Questions about our boats: Q: I misplaced my boat’s owner’s manual. Can I download a copy online? A: Yes you sure can. Download and print by clicking on your preferred file format:

Q: What are the differences in your header pipes? A: We offer three shapes of header pipes: 90 degree, Wrap-to-Center (“WTC”) and Vee (“V”). Click here to view drawing and measurements of each.

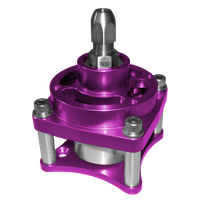

Q: I ordered an anodized Coil Mount “Z” Plate – why is there a silver spot where it looks like someone has drilled a hole in one of the corners? A: If you are looking at the Z plate with the Z facing you, the lower right-hand hole will have some of the metal machined so that the silver is showing. Also, the upper right-hand threaded hole will have silver showing in the threaded area. This is done for grounding purposes. The grey ignition coil must ground all the way through to the main case in order for it to work properly. This is why you will notice some color missing on colored plates. They are not damaged.

Q: Can you tell me a little more about soldering? A: We highly recommend our solder-less drive cable assembly. It uses a round collet to a square ferrule. The cable does not have to be soldered, which means that you have a much stronger connection. If you choose to go with a setup where soldering is necessary, here is what we recommend: Stay-Brite Silver Solder (which comes with its own flux) is the only brand we use or recommend. We use a propane torch with Mapp gas (it burns hotter). General Soldering Procedure: Lightly sand the cable to the length that will be inside the ferrule, clean with acetone, apply the flux to the cable, and slide the ferrule over the end of the cable so the flux transfers to the ferrule. Put the cable assembly into a vise with the cable hanging straight down, and clamp so it supports the ferrule in the proper position. Cut about 3 pieces of silver solder (approx 1/8 inch long each), and drop those into the ferrule – the pieces will rest on the exposed cable. Then take the torch and heat the outside of the ferrule, working the heat around the outside perimeter until the solder starts to melt and flow – immediately pull the heat away. If you apply any heat directly to the cable, it removes the temper and causes failure. Q: How much space do I need between the end of the cable collet and the end of the stuffing tube? A: There should be about 3/4” if your engine is soft-mounted (rubber dampened) & ½” if the engine is solid-mounted. This space allows the engine to move through vibration without damage to the end of the stuffing tube.

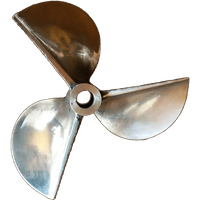

Q: What are the differences between your drive cables/shaft systems? Solder-less? Solder? Hughey? What do I need? A: We know that it’s hard to know what cable is what. We’ve created a diagram for you to make it easy. Click to view the diagram. If you need more explanation, please feel free to contact us! Q: Is it normal for my boat to pull to the right? A: Yes it is, due to the torque of the boat. This can often be adjusted with trim tabs, drive angle or changing your prop. Q: How do I remove the drive cable from my boat? A: In order to remove your drive cable, you will first loosen the two set screws in the shaft ferrule. This will be the tapered cylinder between the transom and the shaft strut. Next, you will loosen the cable collet compression nut, which is the 9/16″ hex nut on the end of the collet. This will allow you to remove the cable. Slide the propeller shaft towards the rudder until it is released from the ferrule, pull the ferrule down slightly until it clears the bottom of the strut, and pull the cable straight out the back. Clean the cable, wipe any grease off it, spray with a penetrating oil to remove any trapped water or any other foreign fluids. Re-grease and store for the winter. To reinsert the cable, simply reverse the process.

Q: How do I properly store my boat during the winter months? A: For those of you who need to store your boat(s) for the winter, (not all of us can live in warm weather year-round!) 1. Remove all fuel from tank and engine. Pump the fuel out of the tank using a pump, siphon, etc. There will be fuel left in the lines, the carb, as well as inside the engine. Generally, it’s recommended to fire the engine and let it idle until the engine quits. This will burn any unwanted fuel out of the engine and carburetor lines. 2. Remove the spark plug from the engine. Use a lightweight lubricating oil such as Marvel Mystery Oil Top Cylinder Lube. This can be purchased from most automotive stores, etc. Pour approximately an ounce of this lube into the spark plug hole. Gently pull the starting cord 7-10 times. Do it slowly so you won’t have oil flying everywhere. This will work the oil down into the engines, ring, bearings, etc, and will help keep rust from setting in. Put the spark plug back into the engine. 3. Remove the drive cable, clean, lubricate, and reinstall. Make sure that any water or rust is cleaned off. 4. Do not store rechargeable batteries with a full charge. You will want to discharge your batteries to eliminate any further future “memory” problems. You do not want to discharge completely – but you do not want to store with a full charge. 5. With a penetrating oil such as WD-40, spray any metal parts that might rust or corrode. Wipe everything down – make sure any grease or moisture is wiped off the parts. You are now ready to store your boat! |

Q.What is the oil to fuel ratio I must use for my boat?

A. We recommend a 25:1 or 20:1 gas to oil ratio. This is 5 or 6 ounces of 100% synthetic oil (we recommend Amsoil Saber Pro or Honda HP2) added to 1 gallon of LOW octane gas (87 to 89). This is ideal for most applications. Do NOT use high octane or race fuel (this can harm the engine). Once you choose the mix ratio, do not vary from it. During engine break-in (typically 1.5 to 2 gallons of fuel through the engine), you should vary your running speed and avoid running full-throttle. Always be careful to not over-rev the engine. We recommend BONZI Break-in Oil(one bottle will break-in 2 engines) for faster break-in with top performance. You will have a break-in period with your engine. Usually it takes about a gallon to a gallon and a half for you to achieve top performance.`

Information on octane measurement methods – Click here (.pdf format) Q: What are the high/low starting settings for my carb? A: Stock Walbro WT-644 carb Stock Walbro WT-603 carb Walbro WT-488 big bore carb Walbro WT-257 big bore carb Walbro WT-813 big bore carb

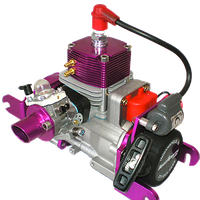

Q: How do I lay out my boat’s engine compartment? A: It is relatively simple. Download the diagram for help.

Q: How does a fail safe work? A: The fail safe is an electronic device that plugs between the throttle servo and the receiver. It senses voltage and frequency changes or signal loss. In other words, if your battery drops to a specific voltage that could cause loss of signal to the radio or if you lose signal between the transmitter and the receiver, it shuts the throttle to a preset position, usually idle, preventing runaways. Q: Why should I keep my boat’s water system clean? A: Keeping your water system clear is important part of a healthy running engine. It is important that all your lines, and if applicable, the water pump, be free of debris, any buildup or kinks in the line. If you are running in salt water, it’s critical that after every day of running, your back-flush your system with fresh water to keep salt residue from building up in the water lines, water jacket, etc. This should be almost a weekly ritual to check all your lines and blow through them to ensure that you are getting adequate flow to keep heat damage from occurring. Q: How long can I run my engine out of the water? A: Any longer than 1 minute can cause overheating and internal damage to the engine. Be very careful not to over-rev as well.

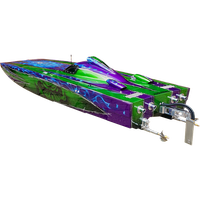

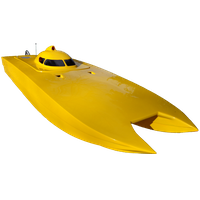

Q: Where should my boat balance? How important is this? A: On v-bottom boats, the balance point is 27-30% of the total length of the hull, measured from the transom (back of the boat). A 50” boat will balance at 13.5” – 15”. Balance is very important. A boat that is too nose-heavy may never get up on plane and will not handle correctly.

Q: How do I install the zero drag seals? Are they hard to install? A: The zero drags are simple to install. Tools Required: Flywheel Puller, Zenoah Engine Tool (or a piece of metal or hard plastic tubing the same diameter of the zero drag to press the zero drag into the rubber seal), Hammer, and Small Diameter Punch (or similar) to tap the “key” out of the slot in the crankshaft. Zero Drag Seals install on each side of the engine crankcase. On the output side (the side of the engine with the collet), slide the zero drag over the crankshaft with the tapered edge toward the seal, and press until it pops into the seal all the way with the flange seating flush against the face of the rubber seal. To install the recoil side, remove the recoil, motor plate and flywheel. There’s a small key (a half moon “key” which holds the flywheel to the crankshaft), remove the key. Now you can repeat the installation process and press the zero drag into the rubber seal until it is seated flush. Reinstall the key, flywheel, mount plate, and recoil and you are ready to go. Zero Drag Seals reduce drag on the crankshaft, creating a smoother surface while retaining the crankcase seal. Installing Zero Drag Seals helps the engine work less reducing wear and tear – while improving RPMs. The improvements are incremental (relatively small), but are part of the process of achieving peak performance. Q. Does BONZÍ have dealers? A. We work with dealers on a limited basis, and have a set purchase minimum once accepted as a dealer. To apply to become a BONZÍ dealer, please fill out the official dealer application. |