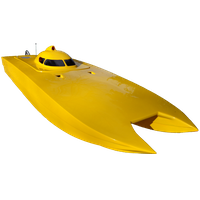

Where should my boat balance? How important is this?

On v-bottom boats, the balance point is 27-30% of the total length of the hull, measured from the transom (back of the boat). A 50” boat will balance at 13.5” – 15”. Balance is very important. A boat that is too nose-heavy may never get up on plane and will not handle correctly.