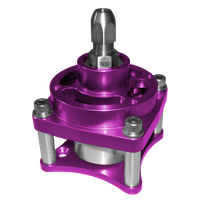

We highly recommend our solderless drive cable assembly. It uses a round collet to a square ferrule. The cable does not have to be soldered, which means that you have a much stronger connection. If you choose to go with a setup where soldering is necessary, here is what we recommend:

Stay-Brite Silver Solder (which comes with its own flux) is the only brand we use or recommend. We use a propane torch with Mapp gas (it burns hotter).

General Soldering Procedure:

Lightly sand the cable to the length that will be inside the ferrule, clean with acetone, apply the flux to the cable, and slide the ferrule over the end of the cable so the flux transfers to the ferrule. Put the cable assembly into a vise with the cable hanging straight down, and clamp so it supports the ferrule in the proper position. Cut about 3 pieces of silver solder (approx 1/8 inch long each), and drop those into the ferrule – the pieces will rest on the exposed cable. Then take the torch and heat the outside of the ferrule, working the heat around the outside perimeter until the solder starts to melt and flow – immediately pull the heat away. If you apply any heat directly to the cable, it removes the temper and causes failure.