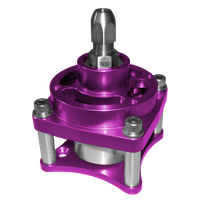

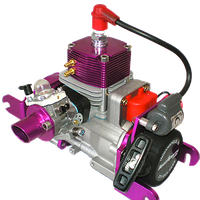

How do I install the zero drag seals? Are they hard to install?

The zero drags are simple to install.

Tools Required: Flywheel Puller, Zenoah Engine Tool (or a piece of metal or hard plastic tubing the same diameter of the zero drag to press the zero drag into the rubber seal), Hammer, and Small Diameter Punch (or similar) to tap the “key” out of the slot in the crankshaft.

Zero Drag Seals install on each side of the engine crankcase. On the output side (the side of the engine with the collet), slide the zero drag over the crankshaft with the tapered edge toward the seal, and press until it pops into the seal all the way with the flange seating flush against the face of the rubber seal. To install the recoil side, remove the recoil, motor plate and flywheel. There’s a small key (a half moon “key” which holds the flywheel to the crankshaft), remove the key. Now you can repeat the installation process and press the zero drag into the rubber seal until it is seated flush. Reinstall the key, flywheel, mount plate, and recoil and you are ready to go.

Zero Drag Seals reduce drag on the crankshaft, creating a smoother surface while retaining the crankcase seal. Installing Zero Drag Seals helps the engine work less reducing wear and tear – while improving RPMs. The improvements are incremental (relatively small), but are part of the process of achieving peak performance.